Filtration is a basic sterilization process used in many laboratories. This approach differs from others in that it does not need killing cells to obtain purity. Filtration, on the other hand, forcibly removes undesirable particles from a liquid. Continue reading to get knowledge of how liquid filtration in the lab works. PTFE Membrane provides a constant, thermally, and chemically suitable barrier against germs and particle matter for device manufacturers.

Liquid Filter Operation Principles

The process of eliminating solid particles, pollutants, and contaminants suspended in a fluid stream is known as liquid filtration. It is a simple procedure that comprises passing liquid, slurries, and suspensions through a filter medium and blocking and retaining the collected particles.

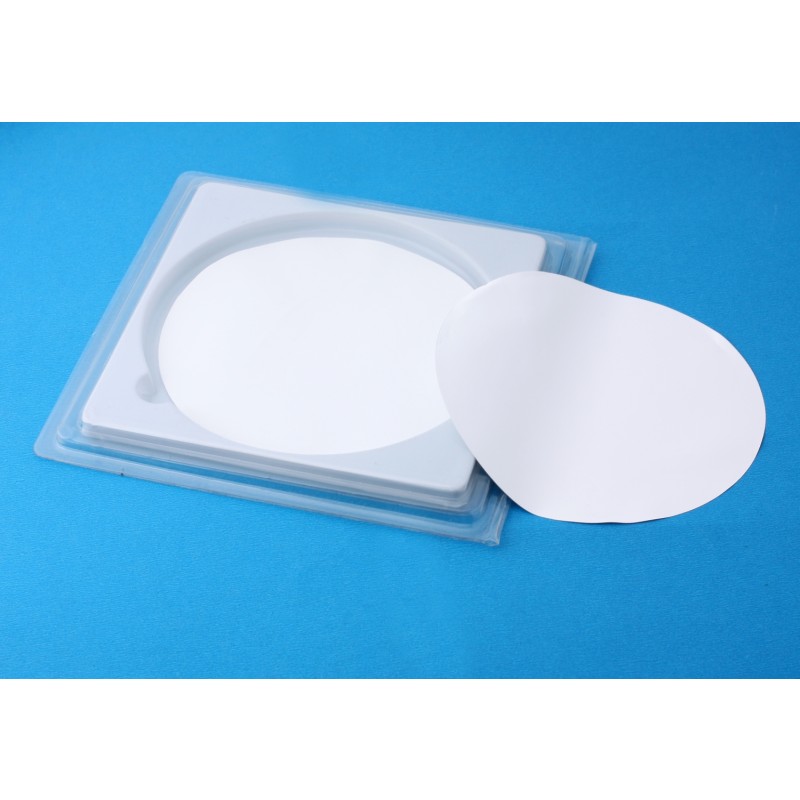

The Membrane Filters media has tiny, microscopic holes or pores that enable only the filtrate to pass through, leaving the undesired particles on the opposite side of the medium. Oversize particles are bigger than the pores of the filter media and cannot pass through it. Over time, the larger particles build up to create a solid layer with a substantial thickness, known as the filter cake. The filtrate is the cleared liquid that is free of oversize.

When fluid flows through the filter medium and the forming filtration process during liquid filtration, it experiences flow resistance. As the cake layer grows, the resistance to liquid flow and pressure drop rise. Cake qualities like porosity properties and particle-specific surface area determine the flow resistance.

Liquid Filtering Methods That Are Often Used in Laboratories

Vacuum Filtration

A vacuum pump accelerates the pace of filtration by producing a partial vacuum and rapidly drawing the fluid through a filter.

Gravity Filtering

It involves pouring a liquid from a higher point into a lower location, where it passes through filter paper that prevents solid contaminants from passing through.

Multi-Layer Filtration

This involves passing a liquid through numerous layers of filtering material. In the direction of filtration, the pores in the filtering material grow finer.

Some industrial filtration equipment can do constant rate and constant pressure filtration. The pressure differential is negligible in small-scale filtering applications, and the process liquid is simply permitted to flow through a filter media secured in a filtration vessel.

Applications of Liquid Filtration

A variety of particles can be removed from a solution using liquid filtering. Liquid filtration may remove viruses, proteins, and poisons depending on the particle size of the filter. One of the primary advantages of liquid filtration is that it does not require heat, as do many other sterilizing processes. As a result, it is an excellent choice for disinfecting heat-sensitive liquids.

The membrane Filters medium is the physical barrier that separates the raw process liquid from the clear filtrate. To ensure a good filtering operation, the material utilized as the filter media must meet the following requirements:

- To achieve a purer filtrate it must bind and hold the solids to be filtered.

- It must be chemically resistant to the fluids under evaluation.

- To endure the material stress imposed by fluid and processing methods! it must be strong and durable.

- To avoid blockage, it must not plug or blind.

- It must be cost-effective, which is defined by the usage.

Conclusion

The liquid is filtered through a membranous filter with small holes. These holes allow liquid to move readily through while filtering out bigger particles. The smaller the pore size, the more particles it screens out and the more energy it takes to push the liquid through. PTFE Membrane does not absorb moisture from air or gases. They are perfect for venting, phase separations, and aerosol sampling. Liquid filters are devices that remove dust and matter from a flowing fluid. A physical barrier, known as the filter media, is required in the filtration process, through which the liquid flows and particles are kept.